2G BioPOWER is aiming to develop a UK project to convert the UK’s used tyres into biofuel whilst recovering valuable carbon black and steel.

Through a UK Govt supported study, it demonstrated that the large scale implementation of pyrolysis technology in the UK is highly feasible. (UK Enviro Project Highly Feasible). Whilst based on Scandinavian Enviro Systems' technology, this analysis will apply to other technologies.

Pyrolysis recovers the carbon black and steel in tyres and converts the rubber to a partially renewable oil. The oil can be converted to biofuel, whilst high-quality recovered Carbon Black (rCB) can be re-used in rubber products including new vehicle tyres. Tyre pyrolysis is therefore a major contribution to the Circular Economy. It both saves energy and GHG emissions are reduced by at least 80% for all products.

Recovered Carbon Black (rCB) is already being used in the manufacture of industrial tyres by Hexpol, in Volvo Car components and for pipe seals.

THE PROCESS

USED TYRES

Used Tyres are shredded or crumbed and heated without air (pyrolysed). This converts all the rubber into oil and gas whilst leaving steel wire and the original carbon black.

One Tonne of Used Tyres will produce:

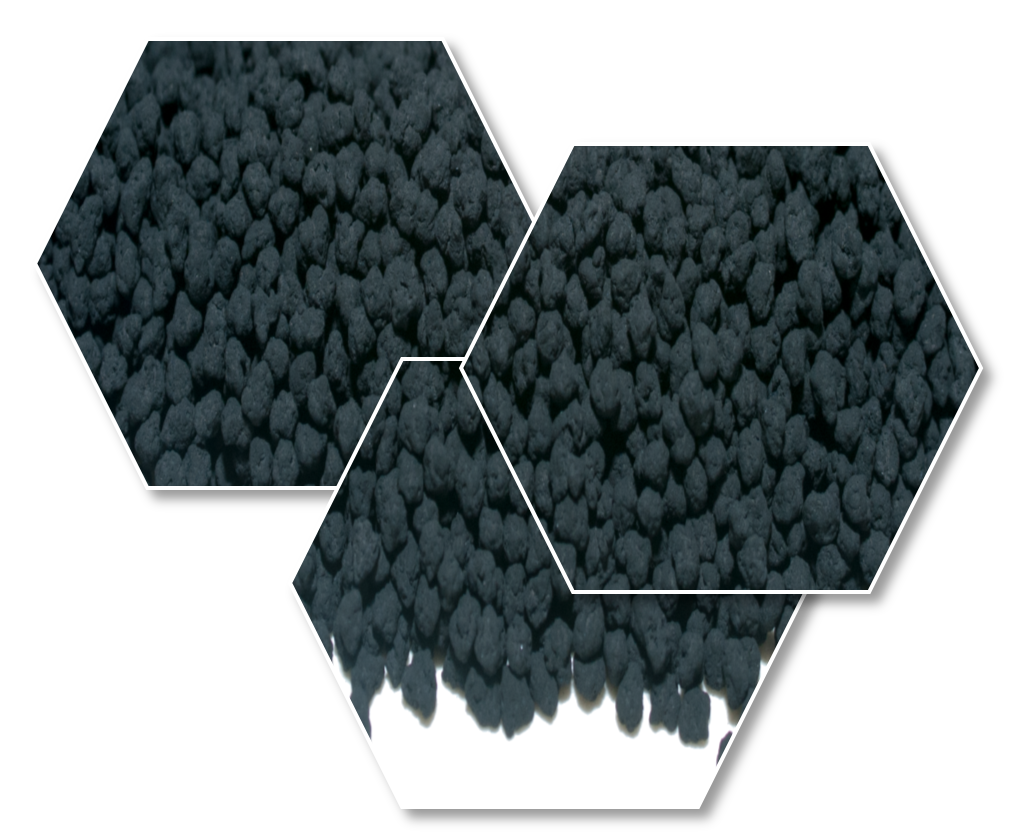

CARBON BLACK (300 kg)

Carbon Black originally used to make the tyres, is recovered along with the other inert fillers. This is milled and beaded for re-use in rubber components. By replacing virgin Carbon Black, recycling Carbon Black (rather than burning tyres) reduces emissions by about 80%. (1kg of virgin Carbon Black is made from ~1.6 litres of fossil fuel).

Recovered Carbon Black (rCB) is now being used in industrial tyres, Volvo Car components and pipe seals. Leading manufactures are now testing it for use in car tyres.

OIL (450 kg)

Oil is produced from the synthetic and natural rubbers in the tyre. The oil comprises ultra-light, light and heavy oil. The ultra-light fraction is used in the process.

Carbon 14 analyses show the oil to be ~ 45% renewable. 2G BioPOWER is has long been supporting regulatory changes and developing the market in order to refine the oil into partially renewable transport fuels.

STEEL WIRE (100 kg)

Steel wire is separated from carbon black and briquetted.

This is a high value waste metal and has attracted interest due to the added carbon it carries. It is clear of any rubber and thus causes no issues in furnaces.